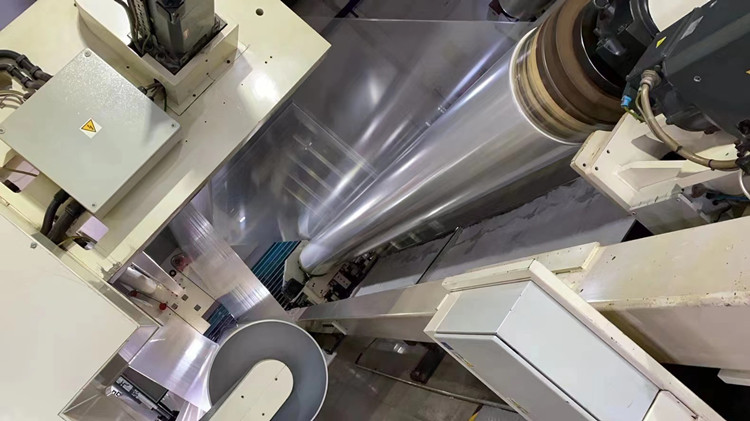

Professional BOPP anti-scratch thermal roll laminating film supplier from China

If you are interested in,Please contact: Emma@grmateril.comFree samples for your test

- Satisfaction Guaranteed

- Action in time

- Worldwide Shipping

Pre-painted film structure consists of substrate and adhesive layer, the substrate is usually PET and BOPP film, from material cost and processing technology considerations, the majority of pre-painted film substrate using BOPP film, thickness of 12-20 microns, adhesive layer thickness of 5-15 microns.

According to the different processing equipment and process conditions, different thicknesses of adhesive layer are used, and the adhesive layer is divided into hot melt adhesive and organic polymer low temperature resin. The difference between the two is that the hot melt adhesive is made by the main adhesive resin and several kinds of materials mixed and modified with tackifier and conditioner, while the organic polymer resin is a single polymer low-temperature copolymer.

Due to the limitations of technology, production equipment and raw materials, there are still quality defects in the pre-coated films produced by domestic equipment (most of them are hot melt adhesive type). Since the production process is similar to that of coated film, the adhesive is dissolved with organic solvent and rolled onto the substrate film with concave anilox rollers, so there is insufficient solvent evaporation, odor when operating and using, and the surface is easy to blister after the solvent evaporates after the film is coated. At the same time, due to the hot melt adhesive by several polymer materials blended, the use of the process, temperature control will cause degradation and cross-linking of polymers within the hot melt adhesive, so that the surface of the film is not good. Some pre-coated film colloid easy to bond with the outer surface of the substrate, resulting in poor roll-up. Due to the thin layer of adhesive, and the surface is not activated by the treatment, it is easy to produce a lack of adhesion to the printed matter and other defects. As the hot melt adhesive is mixed by several materials, the transparency of the laminated film is significantly worse than that of the low temperature pure resin-based pre-coated film.

CHOOSE THE BEST LAMINATING FILM FOR YOUR PRODUCT

The lamination films are divided into groups by the process and by their base materials: BOPP, PET and Nylon laminating film. However, within these groups there are numerous different types of products which all have their special properties. Therefore, choosing the best laminating film for a specific project is not an easy job.

Advantage of our BOPP Thermal Film Rolls :

1. Easy to operate, cost-saving, time-saving and high efficiency.

2. No wrinkle, bubble.

3. Moisture proof and fade proof.

4. Environmentally friendly and non-toxic.

5. Not easy to tear.

6. High quality and competitive price.

Product Description

|

BOPP Thermal Lamination Film

|

||

|

Type

|

Glossy&Matt

|

|

|

Thickness

|

17~ 27 micron

|

|

|

Width

|

200mm ~ 2150mm

|

|

|

Length

|

200m~6000m

|

|

|

Core Size

|

1 inch or 3 inch

|

|

|

Corona Treatment

|

Double sides

|

|

|

Surface Tension

|

≥ 38 dyne

|

|

| Application | ||

| 1. Film lamination for covers of book, magazines, catalogs, documents, picture, etc

2. Film lamination for packaging box, shopping bags, advertisement, etc. |

||

|

Application Manual

|

||

|

Lamination temperature: 85 ~ 105 ℃

|

||

|

Lamination pressure: 5 ~ 15 Mpa

|

||

|

Lamination speed: 8 ~ 50 m/min

|

||

Reviews

There are no reviews yet.