-

BOPP tobacco film, also known as biaxially oriented polypropylene tobacco film, referred to as tobacco film, is made of a variety of polypropylene functional materials for co-extrusion, stretch molding. Domestic manufacturers generally use three-layer (A/B/C) co-extrusion technology by biaxial stretching to produce high-performance BOPP cigarette film, with high transparency and) glossy feel, non-toxic materials, stable molecular structure, a certain degree of odor and moisture barrier function, so it is the ideal material for cigarette packaging.

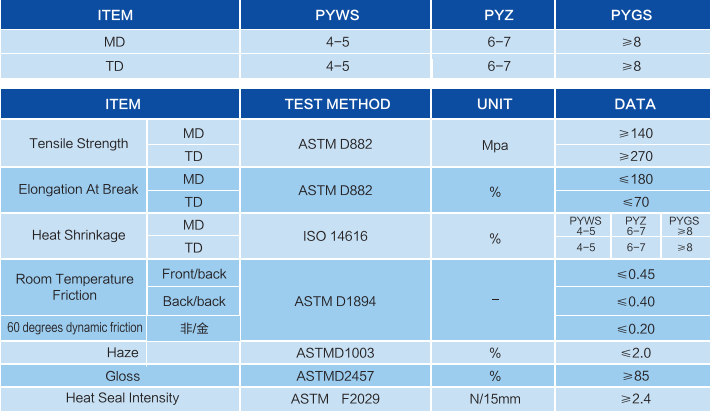

Friction coefficient is a measure of the sliding characteristics of BOPP cigarette film, for cigarette packaging on the machine operation, the appropriate coefficient of friction is important, the film requires good thermal sliding, so as to meet the high speed in the hot state (400 packs /rain ~ 600 packs /rain) slip, so that the packaging line can be opened at full speed without affecting the output. The coefficient of friction of the outside of the film on the metal, especially the coefficient of thermal friction under high temperature conditions must be low. In the cigarette packaging process, the outside of the film in the lower film channel, forming wheel groove, folding plate, iron, rail and other metal parts sliding operation, and because most of these metal parts are operating under high temperature conditions below 50 ℃, with the rise in temperature conditions, the film friction coefficient will rise, after 45 ℃, the film friction coefficient rises quickly, so the film’s thermal sliding performance more to be able to fit the actual packaging machine Working conditions, generally 60 ℃ hot sliding friction coefficient to focus on the control. The other side of the film and cigarette packet box paper friction coefficient should be controlled higher, that is, the formation of the film inside and outside of the differential sliding characteristics, in order to facilitate the positioning of cigarette packets in the forming wheel and the film is well positioned to improve the quality of folding to obtain a compact packaging effect. As BOPP slip enhancer is usually migratory, it needs a period of storage to migrate to the film surface to give full play to the film, that is, the film will be very smooth after a period of storage.

Reviews

There are no reviews yet.