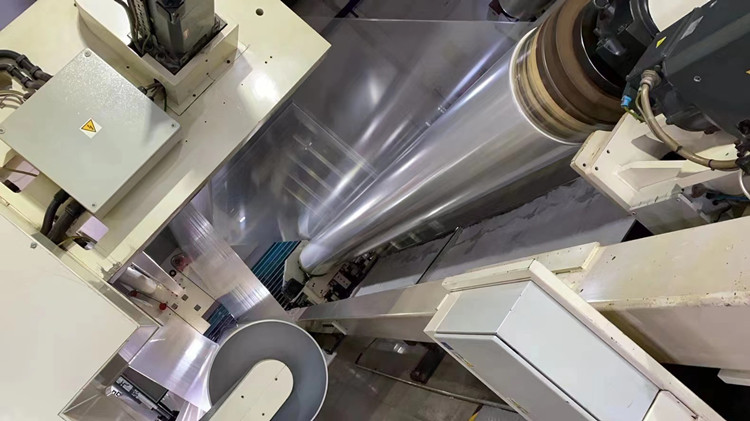

Custom metallised thermal laminating film manufactur

If you are interested in,Please contact: Emma@grmateril.comFree samples for your test

- Satisfaction Guaranteed

- Action in time

- Worldwide Shipping

First, because the pre-coated film lamination process does not produce any harmful substances, therefore, the pre-coated film lamination process is more environmentally friendly.

Secondly, the pre-coated film lamination process is simple, and there is no need to adjust the glue before production, like the instant film lamination process. During the production process, there is no need to control the amount of glue applied and no need to dry the adhesive. It only needs to control the temperature, pressure and speed, and the shutdown is also simple, no need to clean up the glue application mechanism.

Third, the production will not produce bubbles, wrinkles, film release and other phenomena, so the lamination product quality is higher.

Fourth, a wide range of adaptation to the laminating equipment, you can use pre-coated film laminating equipment or namely coated film laminating equipment, but also plastic sealing equipment.

Fifth, pre-coated film lamination process because there is no organic solvents and other combustible substances, so you can effectively prevent the occurrence of fire accidents in production, a higher safety factor.

Sixth, high production efficiency.

Why is the film lamination method is still widely used in the domestic application Although the comprehensive performance of the pre-coated film lamination method is better than that of the film lamination method, but the current situation of the domestic lamination industry, the vast majority of domestic enterprises are still commonly used in the film lamination process. The main reason can be summarized as the following aspects.

One, pre-coated film laminating technology in the domestic start relatively late.

Second, the production of pre-coated film has high technical content, complex process, large investment in equipment, the average enterprise does not have the ability to invest in pre-coated film production lines.

Third, due to China’s excess labor resources and low labor costs, material costs account for a significant proportion of the overall cost of the laminating process. And the cost of pre-coated film is higher than that of coated film, which will inevitably affect its application.

Fourth, the domestic laminating equipment manufacturers produce equipment mostly ready-to-coat film laminating equipment.

Fifth, although the Chinese government emphasizes the environmental protection of the industry, but specifically for the laminating industry laws and regulations have yet to be improved.

Product Introduction:

Material: Bopp/PET, Laminated Material, BOPP/PET+Eva

Types Of: Metallized Film

Use: Packaging Film

Special Performance: Moisture Proof

Processing Technology: Multiple Extrusion

Transparency: Opaque

Feature: Moisture Proof

Usage: Packaging & Printing

Packing: Roll packing & Carton

Paper Core: 1″/3″

Place Of Origin: Shandong, China

| Selling Units: | Kg or Square Meter |

| Package Type: | Bubble Bags or Carton Boxes |

The Metallized Thermal Lamination Film are usually packed as Metalized Thermal Laminating Film roll, it is produced by metallized BOPP/PET Film and EVA glue, we use extrusion coating process to combine the two layers. It makes the package look nice, precious and high value.Gold&Sliver Metalized Thermal Lamination Film comes out as the gold aluminum paper when it laminates on presswork. Now it is widely used to laminate on the daily consumable packing box, such as the box of grocery, medicine, wine, comestics, etc. Our metalized thermal lamination film is available in gold and silver. However, if you have special requirements for other colors, we can customize it for you.

This film has strong adhesion and perfect surface tension, with double side corona treatment.

It is BOPP based, metalised and one side treated thermal laminating film. Film has extrusion coated surface on metalised with low temp. melting resin, which enables the lamination of film to paper products by heat and pressure.

We supply metallized pet thermal laminating film in silver,gold and other colors (available at both glossy and matte), mainly at 24micron

Advantage of our Metalized BOPP Thermal Lamination Film

1. Environmental friendly and non-toxic

2. Not easy to tear off

3. Moisture proof and fade proof

4. Anti-aging, longer service life.

5. Compared with aluminum film, cost is less and price is competitive.

|

Applications

|

||||||||

|

||||||||

|

Application Manual

|

||||||||

|

Lamination temperature: 85 ~ 105 ℃

|

||||||||

|

Lamination pressure: 5 ~ 15 Mpa

|

||||||||

|

Lamination speed: 8 ~ 50 m/min

|

||||||||

Reviews

There are no reviews yet.