Customized Matte Laminating Film For Packaging Manufacturer

If you are interested in,Please contact: Emma@grmateril.comFree samples for your test

- Satisfaction Guaranteed

- Action in time

- Worldwide Shipping

The BOPP Thermal Laminated Film is widely used in packaging and printing industries. It has two layers, it is BOPP Film with extrusion coated by EVA glue. It has two layers, one Layer has Bopp film properties and the other Layer becomes heat sensitive surface used for dry laminator. Thermal Laminating Film is available in different finishes ranging from Matte to high gloss depending on the the material the film ia made of. It applied to surfaces such as paper, cardboard, aluminum foil etc. We can provide both Matt Thermal Laminated Film and Glossy Thermal Laminated Film for packaging and printing usage.

The process of pre-coating and rewinding plastic film and then laminating it with paper prints.

Pre-coated film refers to the process of pre-gluing and rewinding plastic film and then laminating it with paper prints. It is first applied by the pre-coated film processing plant according to the specifications and width, and then coated on the film and rewound for the use of manufacturers to choose, and then laminated with printed materials. Laminating, or laminating, is a processing technology in which plastic film is coated with adhesive and bonded with paper printed materials after heating and pressure to form a paper-plastic product. By the lamination of printed materials, due to the surface of a thin and transparent plastic film, the surface is smoother and brighter, thereby improving the gloss and fastness of the printed materials, the graphic color is more vivid, three-dimensional, while more waterproof, stain-resistant, wear-resistant, folding, chemical corrosion resistance.

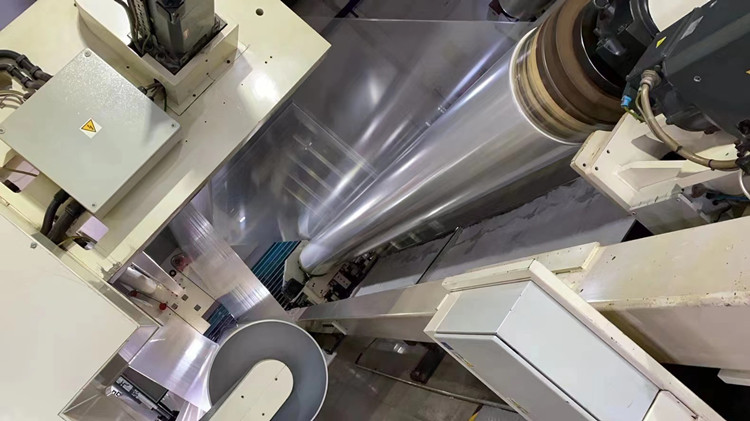

Pre-coated film laminating machine is a kind of laminating equipment with the least investment and the best effect, precisely because the pre-coated film laminating machine adopts an environmentally friendly laminating process, and the operation is

Simple, less investment, easy to use, whether mass production, or a small amount of lamination, the use of all can be handy, the market is widely used.The laminating machine is a small laminating machine. So the market potential of small laminating machine is huge, the use of laminating machine for printing post-processing products are bound to have a strong market competitiveness. We develop and sell a series of small laminators is to bring the most affordable, most direct and convenient service to the majority of users.

Paper Core: 1 inch or 3 inch

| Selling Units: | Kg or Square meter |

| Package Type: | Bubble bags or Carton boxes. |

Advantage of our BOPP Thermal Film Rolls :

1. Easy to operate, cost-saving, time-saving with high efficiency.

2. No wrinkle, bubble.

3. Water proof and fade proof.

4. Environmentally friendly and non-toxic.

5. Not easy to tear.

6. High quality and competitive price.

Product Description

|

Type

|

Glossy& Matt

|

|

|

Thickness

|

17~ 27 micron

|

|

|

Width

|

200mm ~ 2100mm

|

|

|

Length

|

200m~6000m

|

|

|

Core Size

|

1inch or 3 inch

|

|

|

Corona Treatment

|

Double sides

|

|

|

Surface Tension

|

≥ 38 dyne

|

|

|

Shelf Life

|

12 months

|

|

|

Delivery Time

|

Generally 15 days but it depends on the items and the quantity of order

|

|

| Applications | ||

|

1. Film lamination for covers of book, magazines, catalogs, documents, picture, etc

2. Film lamination for packaging box, shopping bags, advertisement, etc.

|

||

| Application Manual | ||

|

Lamination temperature: 85 ~ 105 ℃

|

||

|

Lamination pressure: 5 ~ 15 Mpa

|

||

|

Lamination speed: 8 ~ 50 m/min

|

||

Reviews

There are no reviews yet.